Selecting an Asset Tracker

Boats, Generators, Trailers, Tanks, Trains, Pumps, ATVs.considerations when selecting an Asset Tracker

Understanding the balance

With the large variety of asset trackers available, selecting an asset tracker that will best fit your fleet and maintenance schedules may seem like a confusing task at first. Fleetistics has made it much easier for you. All the asset trackers we provide have undergone rigorous testing for quality assurance and our team of knowledgeable sales professionals are ready to assist in making the perfect choices tailored to your specific needs. Continue reading for an in-depth look into the many differences between asset trackers.

There are three main variables that must be prioritized and balanced when selecting an asset tracker that best suits the needs of your fleet and equipment.

- Data resolution (Reporting Intervals)

- Investment/Cost (Hardware and Monthly Service)

- Network Coverage (Local, Nationwide, Global)

Data Resolution

Determining the amount of data you need will factor into the overall monthly costs. An asset tracker which generates one location update per day for simple inventory management is far less expensive on a monthly basis than an equipment tracker reporting location information and engine diagnostics every five minutes. It is likely you may have the need for different varieties of asset tracking solutions throughout your fleet encompassing the entire available range of reporting options. Fleetistics consultants will help you identify which asset trackers and reporting rates will provide the most benefit for your fleet.

Do I need reports every 1 minute? Every 5 minutes? Once an hour? Once a day?

Investment/Cost

Cost is reflective of a variety of standard and/or additional features such GPS tracking resolution, engine diagnostic data, accelerometer data, overall device construction and sturdiness, and the communication network used to transfer the data. Balancing cost against the other variables is a key decision when selecting an asset tracker. Generally, the devices will be of better build quality and will perform longer the more they cost up front. You will find a range of data plans for asset trackers from $15 monthly for small quantities, to $9 monthly for large volume orders. Asset tracking units themselves will vary more widely from about $150 to $300 for small quantities. Contact Fleetistics to see if you qualify for volume pricing.

Plans ranging from $9-$15 per month and devices from $150-$300

Network “Coverage”

Standard communication networks:

Satellite communication networks provide real-time communication in very remote and non-urban areas while covering most of the planet. Satellite communication can be more sensitive to environmental conditions such as trees and buildings, and it is important to have an unobstructed line of sight with the sky to provide contact with the orbiting satellites. Satellite communication is also significantly more expensive than terrestrial cellular communication. For this reason, the interval of reports and the amount of data typically needed is much less. Only specialized systems and industries provide high resolution satellite tracking because price is not a concern. Think about the monthly cost difference between a satellite telephone and a cell phone. The same modems used in phones are often used in GPS asset tracker.

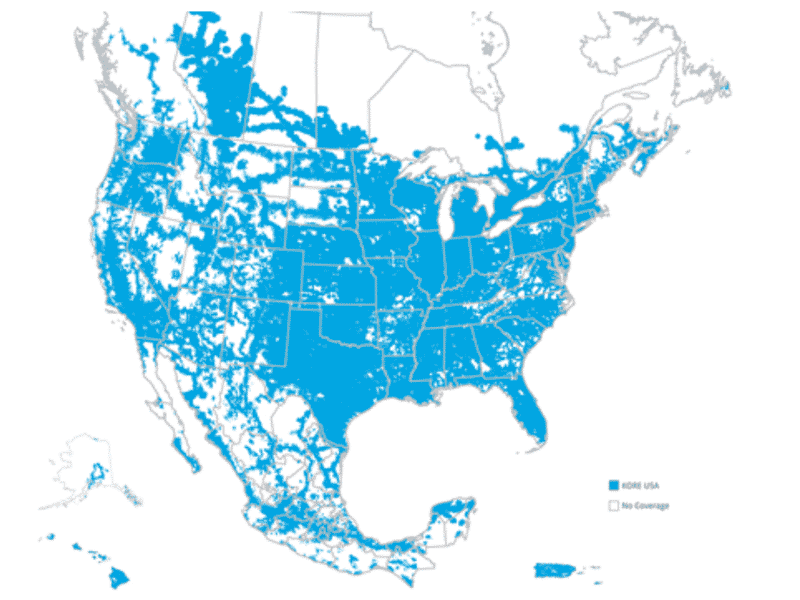

Cellular communication networks offer the ability to deliver higher amounts of data and detail for a very affordable rate. These are the same networks that we use to browse the internet on our cell phones. Cellular networks provide great coverage in populated areas but just like when you’ve gone camping with the family in a remote area sometimes you will find that your phone no longer has a signal for long periods of time. Northern Canada, Alaska, South America and parts of the US don’t have much cell coverage, however most cellular tracking systems will store data when not in coverage and will transmit it when the GPS tracker returns to cellular network coverage ensuring your data is not lost.

Asset Tracker Hardware

There are three primary ways to power an asset tracker. Some systems offer a combination, but few will do all three. The four options can be found on GPS trackers that work on either the satellite communication network and the cellular communication network.

- Vehicle or asset power

- Battery

- Solar

- Combination

Battery Powered Asset Trackers offer a very convenient installation process. New units can be mounted with screws or with a magnetic base. There is no need to run wires for power and most anyone can do the installation. When considering a battery powered asset tracker, it’s good to plan for eventually replacing or recharging the batteries as they approach the end of their life cycle. A batteries’ lifespan will depend on the reporting rate chosen for the unit. More frequent updates will drain the battery faster than less frequent reporting intervals.

There are three battery options, rechargeable, non-rechargeable but replaceable, and non-rechargeable and non-replaceable. All three battery options have appropriate applications. Rechargeable batteries can easily be added to a maintenance schedule and charged every year or as needed. Most replaceable battery trackers use lithium-ion batteries that can be purchased off the shelf, but some asset trackers have proprietary batteries that will need to be special ordered. If using a unit that requires a proprietary battery it is best to maintain an inventory on hand so you will always have replacements when needed. Rechargeable batteries are typically smaller because they are meant to be recharged more often. Non-rechargeable, non-replaceable batteries are generally the largest and the entire GPS device is discarded when it expires. It’s important to understand your expected battery life and recharge or replace batteries before they completely drain to avoid losing contact with the asset.

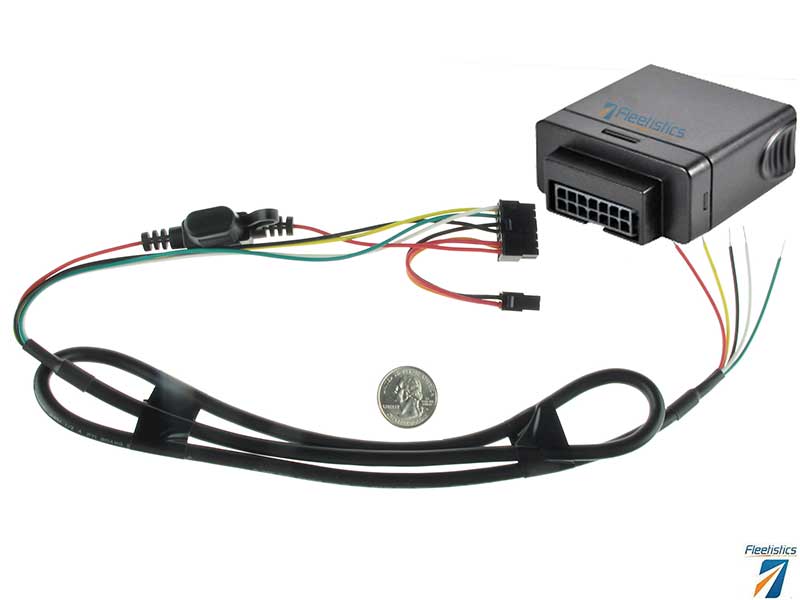

A 3-wire powered asset tracker is wired to the power supply of the equipment or asset being tracked. This ensures that it always has power so the requirement for a backup battery may not be as important. Many fleet managers prefer powered asset trackers that have backup batteries to track the asset when it is not in use. This is helpful for inventory and theft mitigation. Backup batteries are not intended to last as long as a dedicated battery asset tracker so be sure you understand the requirements for battery power when the GPS tracker is not getting power from the asset’s own power system.

Solar powered asset trackers are becoming far more popular because they reduce the need for battery maintenance and provide an easy installation. Solar powered asset trackers are a good choice when selecting an asset tracker when the goal is an easy to maintain and reliable GPS tracker that will last for 3-5 years. After 3-5 years, replacing the device is often needed. Solar units may not be the best choice when more frequent update rates are desired because they are slower to recharge and require a lot of sunlight. Climate can also affect their ability to recharge. Fleets that operate in long snowy winters may have more difficulty keeping the units powered than fleets that tend to stay in warmer more temperate parts of the country. If you are installing a device on a fixed asset, pay attention to the angle of the sun and mount it on the appropriate side to get the most sunlight.

Selecting an Asset Tracker for Harsh Conditions – Asset Tracker Construction

How an asset tracker is constructed is important, as not all asset trackers are built with the same amount of weather proofing. Some asset trackers meet military specifications and have a price tag to match. Most asset trackers are made for commercial applications and have a compromise between durability and price. Matching the construction to the intended application will provide for a longer life. Most asset trackers come with a 1-year warranty against standard defects, but this does not include water or sand intrusion. To be safe, never pressure wash an asset tracker at less than 3 feet. The thickness of the material, number of screws (or lack of any screws in a molded device) and the seal around the wiring harness if applicable contribute to the life expectancy of an asset tracker. Extreme heat and cold can also play a big part in the longevity of the device.

IP Rating

Quality asset trackers will be IP rated which means they have been tested to meet an international standard for water, dirt, vibration, and other known hazards. The lower the IP number, the less durable the asset tracker will be. You want to see IP-67 or IP-68 for asset trackers.

Intrinsically Safe is defined as “equipment and wiring which is incapable of releasing sufficient electrical or thermal energy under normal or abnormal conditions to cause ignition of a specific hazardous atmospheric mixture in its most easily ignited concentration.” Intrinsically safe is often a requirement when operating around liquid fuels and explosives. If intrinsically safe is needed, the number of asset trackers available is far fewer. This is often a specification in the oil and gas industry. View more info at https://en.wikipedia.org/wiki/IP_Code

Investment

The two primary considerations for budgeting is the cost of the GPS equipment and the monthly subscription service. Some features are standard and others that are normally available may be turned off to start and provided at a slightly higher cost later when you realize you would like to have that specific feature. The best things to do is to contact Fleetistics and allow us to customize a solution and provide all the features you need at the best price available.

Backup Battery Performance

A backup battery can play a key role but batteries have limitations ranging from last gasp transmission, to a reduced reporting profile so the battery can last longer if the main power is disconnected. There is a difference between battery types such as Li-ion verse NiMH batteries and whether the batteries are off the shelf or special order and very expensive. Get a clear understanding of the battery size and expected performance so you can make a good decision.

Make a Checklist for Selecting an Asset Tracker

- IP-67 rated – required

- Do you need a backup battery to aid in theft recovery?

- Do you need an equipment tracker or asst tracker (see above) ?

- How frequently do you need to get position information?

- Do you need satellite communication or will cellular work?

- Do you need a powered or unpowered GPS tracker?

- Do you need an integrated solution with fleet vehicles?

- Do you need engine hours for maintenance or rental data?

- Do you need engine diagnostics or telematics data?

Right Data

Ultimately the asset tracker selected has to deliver the data YOU need, not what the sales rep wants to sell you. Having a clear understanding of what is required from the data before shopping for an equipment tracking system will make the buying process more efficient.

It is important to keep the list of required data as short as possible. The more required data, the fewer the choices. If engine hours are required, almost any equipment tracker will work. If engine diagnostics codes from a CAT are needed, the choices are very limited and often expensive relative to less capable asset tracking systems.

Equipment tracking might be part of a bigger fleet management program. Therefore, the data provided by the equipment tracker may need to look like vehicle tracking data and be in the same interface. A system like the Geotab system enables fleet managers to see similar data, in the same interface and set the same alerts and reports. This convenience saves time in more complex fleet environments. If the requirements are simple and static, an independent system which is lower in cost might do the trick.

Installing Asset Trackers

Installing an asset tracker or equipment tracker can be a challenge or as simple as screwing it to an asset, depending on your intended use. The type of material and angle of the asset tracker have a lot to do with getting good GPS location information. GPS trackers have a directional antenna and facing the antenna toward the ground or putting it against metal will degrade the GPS signal. For instance, putting the GPS unit in the engine compartment is often not going to work.

As an anti-theft device, place it in a location that is not obvious to a thief. The challenge is hiding it and getting good GPS reception. GPS signals are blocked by metal so be sure to test the location before putting everything back together. One idea is to put the GPS device in the light housing. Customers have purchased amber light housings on eBay for $20 and hid the GPS inside.

Put the GPS system in a location where it is not likely to get pressure washed. The driver is going to will not know or pay attention to the IP-67 limitation of not pressure washing it from less than 3′. The driver might accidentally wash it forcing water into the unit which will not be covered by the warranty.

Protect the connections by soldering the connections and then putting heat shrink tubing over the connections. Ideally, the connections are also protected from pressure washing. You may need to build a shield or put the unit and connections behind something to protect it.

If you have a need to track heavy equipment (yellow iron), skid steers, ATV, utility carts, trailers, train cars, cargo containers, generators, boats, motorcycles or just about anything, contact Fleetistics. With 18+ years of asset and vehicle tracking experience, Fleetistics provides a complete line of solutions to meet your needs.